MaxControl CNC Software

Push your CNC limits to the max with Plazmax’s latest proprietary software.

More than three years of inhouse development by two fulltime software engineers, Plazmax have designed and built their own proprietary CNC software.

The result of this is ‘MaxControl’, a new and innovative controller that allows us to push our cutting tables to limits no other CNC software is capable of doing.

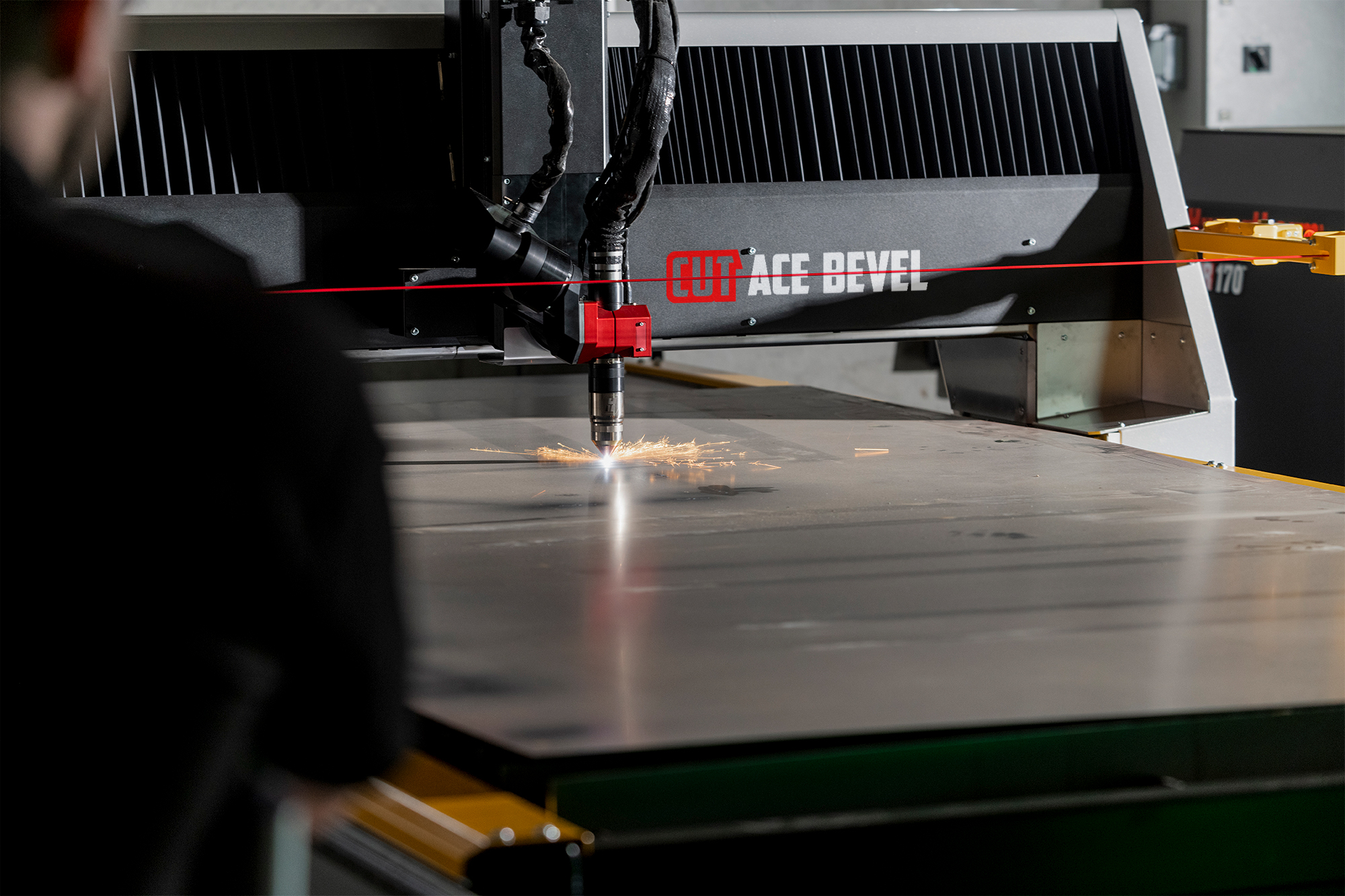

Cut perfect bevels with our advanced controller

Aside from the optimisation of functionality in the vertical cutting position, the new controller also allows bevelling to move to a whole new level and allows our machines to cut bevels using any geometry whilst still producing a high-quality finish.

Additionally, the user interface has been simplified by removing unnecessary steps in the job loading process. By doing this, the controller increases productivity and decreases the chance of user input errors.

Connect with industry 4.0 apps and machines effortlessly

Another massive benefit is the optimisation of our system in readiness for Industry 4.0 and means the controller is ready for integration with any other Industry 4.0 applications and machines.

The controllers interface is both intuitive and easy to learn

This reduces training time for staff and makes the process of loading new jobs faster and reduces the risk of making costly mistakes.

The controller when combined with our proprietary laser height sensing technology makes our machine significantly faster than any other machine in the market – initial testing shows the speed gains over the course of cutting a full nest to be at least 25%.

Finance Options

Although it’s obvious to most the Return On Investment a high-tech piece of equipment can provide, banks and lenders don’t always understand your industry and the importance of such purchases.

Related Product

Plazmax CutAce

Precision plasma cutting with best in class speed and productivity features